Lab-Robots vs. Liquid-Handlers: What’s the Real Difference?

Category: Benefits Robotics Sustainability

Reading time approx: 2 min

Category: Benefits Robotics Sustainability

Reading time approx: 2 min

Whenever we visit a QC lab, the first remark we hear is:

“Why is your Lab Robot different than the Liquid Handler we use?”

it’s a fair assumption. Both systems move along X, Y and Z axes and both take manual work off someone’s bench. Yet comparing them is like comparing a coffee grinder with a fully-automatic espresso station: they both grind beans, but only one hands you a finished cappuccino.

This article unpacks three core differences—process scope, modularity and integration—so you can decide which solution actually fixes the bottleneck in your lab.

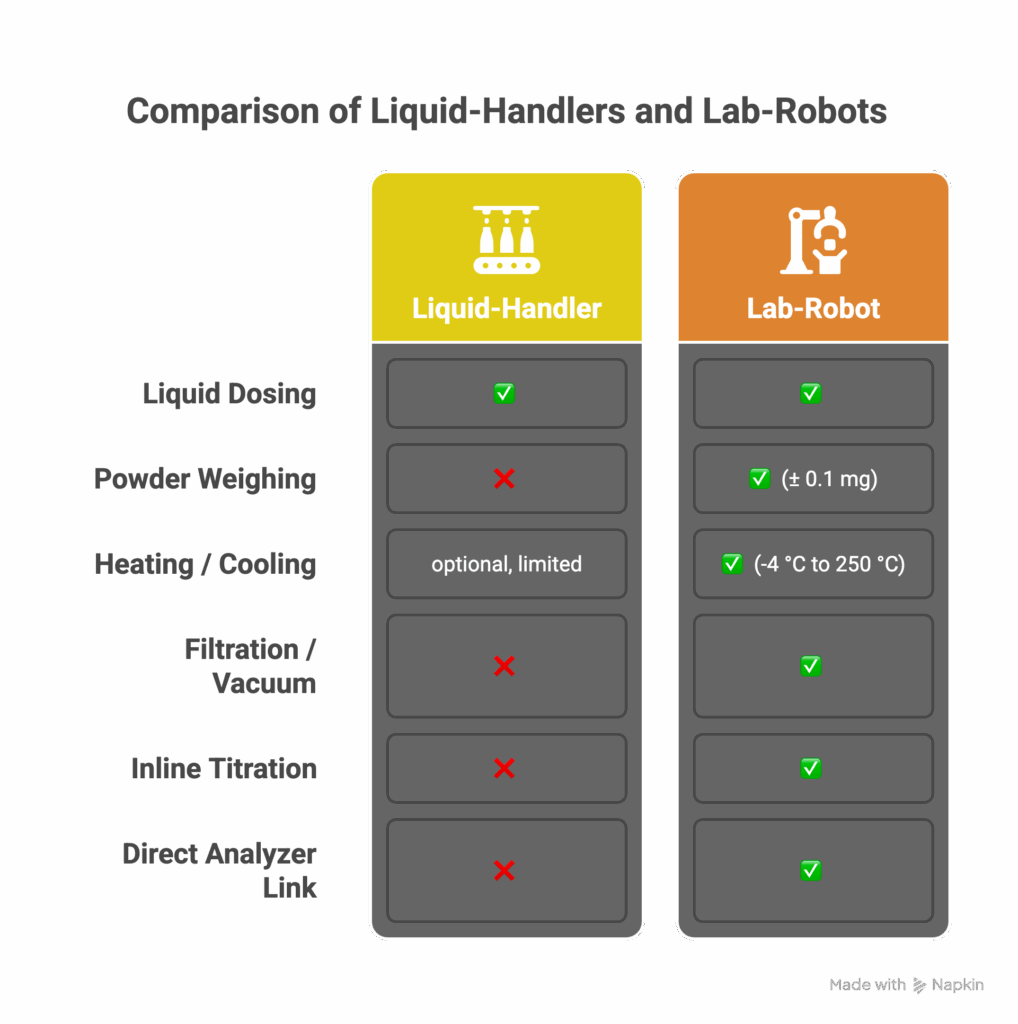

Liquid-handlers were born in biotech. They shine at transferring nanolitres between 96- or 384-well plates, fast and reproducibly. But their world usually ends with water-like liquids. Put 5 M HCl, dense ore slurries or statically charged powders on the deck and their prowess fades.

A lab-robot, such as the Alsys Compact or High-Performance platform, is built to take over the entire wet-chemistry workflow: weighing solids, dosing acids, heating, cooling, titrating, filtering and even handing the sample straight to an analyser.

Key takeaway: a lab-robot treats heterogeneous, aggressive samples as easily as water. A liquid-handler, no matter how clever the script, will not suddenly weigh crystalline ammonium sulphate or swirl boiling acids.

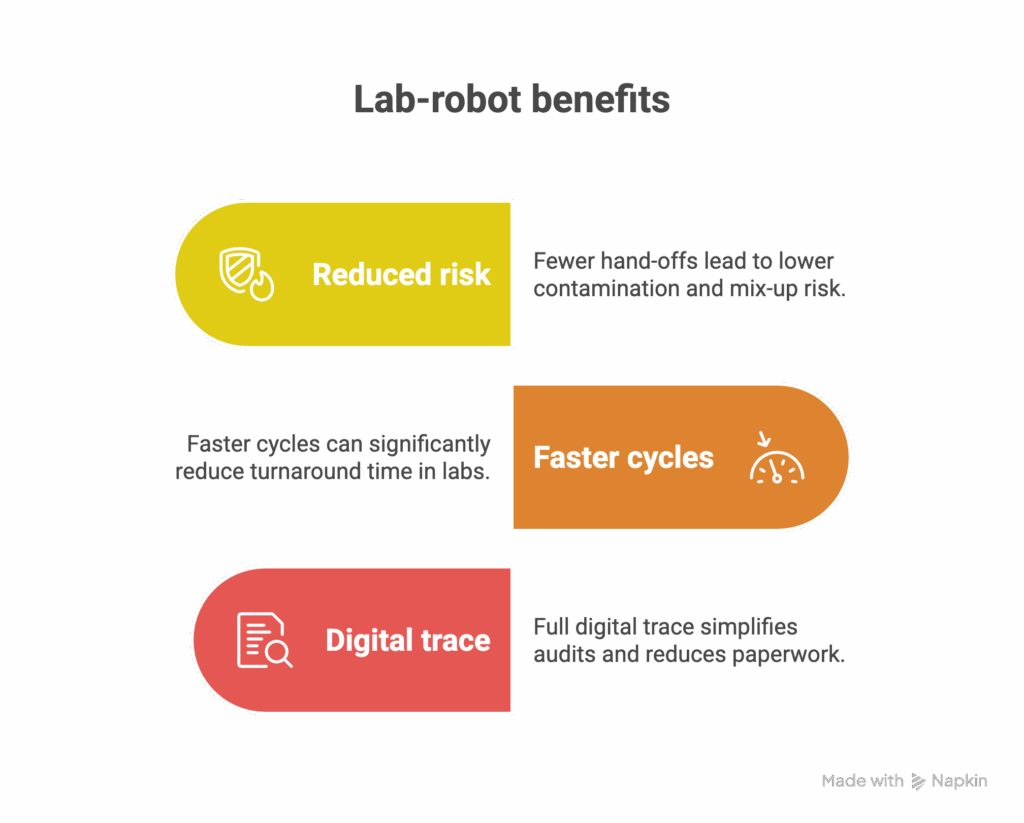

Liquid-handlers have a static deck: tip racks here, waste there, plates in the middle. Need an extra function—titration or filtration? You bolt on separate instruments, doubling software and tubing.

A modular lab-robot, on the other hand, uses its gantry as a backbone; functionality sits in pluggable modules—micro-balance, heater-shaker, filtration cell, titration cup, pH probe lifter. A fertiliser plant can start with weighing + acid dosing and, a year later, add a titration or UV/Vis bridge without moving the frame or learning new software. Our service team swaps the module in a single visit and the same robot runs for another decade.

Field example: A copper refinery began with two modules for Ni and Co titrations. Rising lithium demand hit: we installed an ion-chromatography module and filtration deck without pulling the robot off the floor.

Stand-alone instrument

A liquid-handler is one slice of toast. Once pipetting ends, an operator carts plates to a heater block, centrifuge or titrator. Each hop needs human hands and another login; traceability lives in spreadsheets or limited LIMS plugins.

One-box workflow

A lab-robot is single inlet, single outlet: samples and reagents go in, digital results come out. The robot drives the analyser—titrator, ICP, UV/Vis—inside the same enclosure and logs every move under one batch ID. Auditors get a single PDF instead of a ring binder.

Results

A base liquid-handler costs €50–120 k—tempting. Add tip boxes, plates, extra gadgets and operator time and the cost per sample climbs quickly. A lab-robot’s capex is higher, but it compresses the whole chain.

| Cost factor | Liquid-handler route | Lab-robot route |

|---|---|---|

| Initial capex | €50 k – €120 k (avg.) | €200 k to €800 k |

| Consumables | High (tips, plates) | Low (reusable racks) |

| Hands-on time | Remains high | Drops to monitoring |

| Lifetime / upgrade | 5–7 y, limited retrofits | 21.4 y, module upgrades |

If prep is your bottleneck—not the analysis—robots often pay back in 18-24 months.

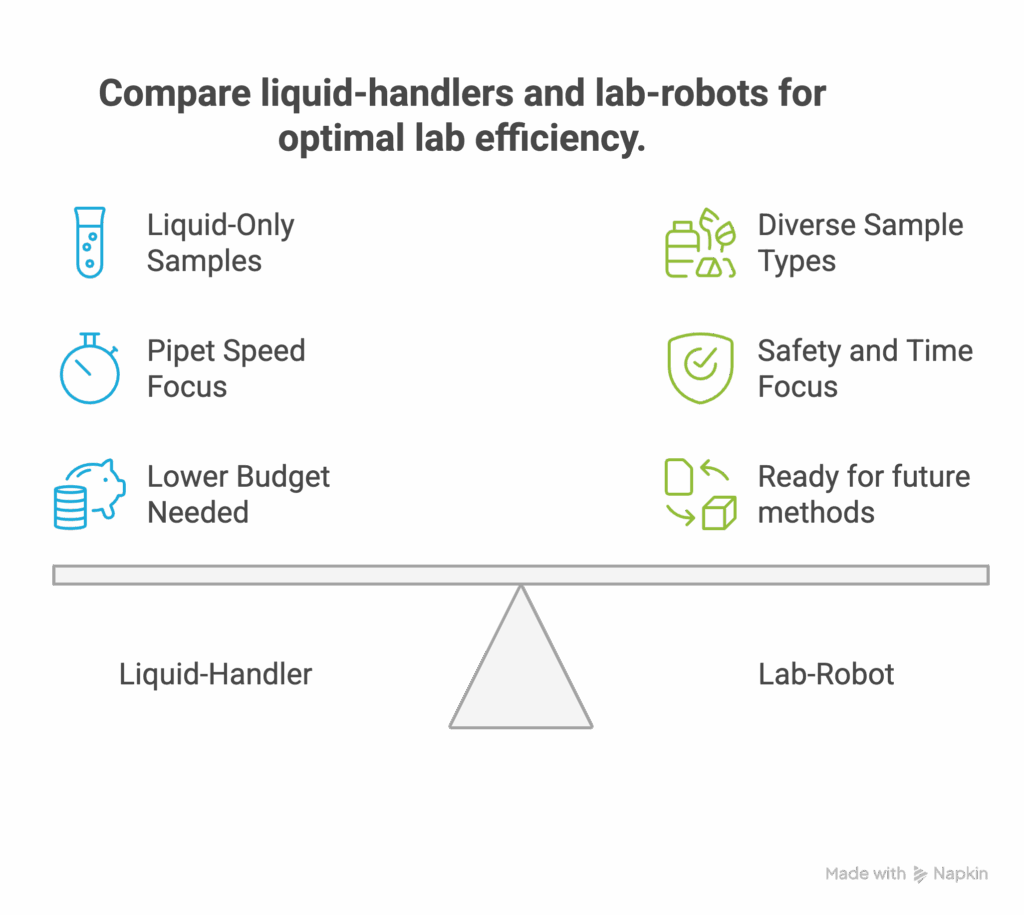

Choose a liquid-handler if…

Choose a lab-robot if…

Liquid-handlers are superb pipette mills. A lab-robot is a miniature production line in a cabinet: it weighs, doses, heats, titrates and even calls the analyser—while shielding analysts from corrosives and logging every step.

Over to you: Which prep step eats most hours in your lab— weighing, dosing or pH balancing? Drop us one line; we will send a no-strings flowchart showing how that step fits inside a robot.

Modular Robots. Measurable Results.